Ford is testing a revolutionary sideways 3D printer that can work non-stop and prints with micro-pellets, similar to sand

As technology continues to develop, automakers are also becoming interested in 3D printers. The new devices promise faster realization times, the use of different materials and above all lower costs. Of course, the use on a large scale is still to be verified, but in the meantime something is moving. And even giants like Ford are trying to have their say on the matter.

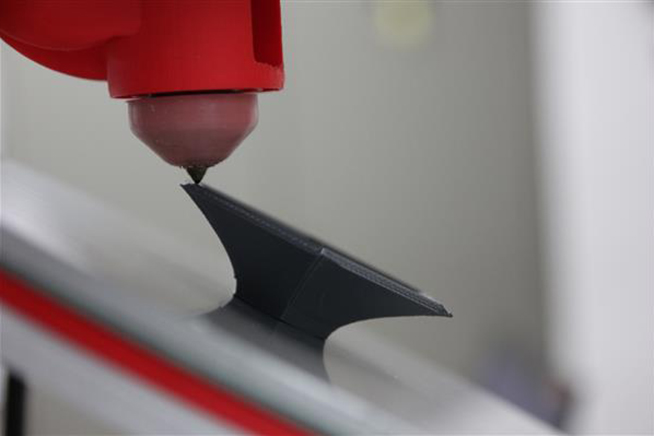

The automaker based in Michigan, in the United States, is testing additive manufacturing (the process of joining 3D printed materials) through a new tool still in beta phase. It’s an innovative 3D printer called the Stratasys Infinite Build 3D Printer. Unlike traditional 3D printers currently on the market, it doesn’t work layer by layer upwards, but prints sideways. This means it can produce much larger objects, theoretically infinite in size. The printing process is totally different, first the substrate is made and then the rest of the product.

How it works

Unlike classic 3D printers the Stratasys doesn’t use filaments to make the final products. In fact, the device works with a special micro-pellet, which looks almost like sand to the eye. To print the material is heated until it liquefies and then fired from the print head. In practically the same way as the injection molding technique. The printing arm is recharged by a robot. And the reloading process can also be done during printing. Basically, the printer can work without ever stopping. That’s incredibly important for automakers.

First Results

Ford has been testing the Stratasys for a couple of months. There has been no shortage of errors and problems, but overall, U.S. engineers have been pleased with the early results. In a short time they have realized that the orientation of the objects is fundamental to get a better and better printing quality and the finishing can be adjusted directly from the printing speed. Ford, however, is not the first company to use this printer, in the past has been used to make prototypes of medical machinery and parts of Boeing. In the U.S. company, however, there is the desire to continue to work on this road for two fundamental aspects: the printer can always work, just a system of cameras and sensors to control it, and almost every part of the vehicle can be made by the same machine. Certo da qui a vedere su strada una macchina interamente realizzata in questo modo passerà del tempo, intanto però alcune parti e molti concpet verranno realizzati in questo modo. Migliori saranno i risultati e minori saranno i tempi.

Fonte foto: ZHAW

Fonte foto: ZHAW

Premi sull’immagine per scoprire la stampante antigravitazionale realizzata dall’Università di Zurigo